The autoclave is a specialized device that uses saturated steam at high temperature and pressure for sterilization. It is recognized worldwide as one of the most reliable sterilization technologies. With broad applicability and a precise user base, it is widely used in scientific research, healthcare, pharmaceuticals, food processing, and higher education.

Product Features:

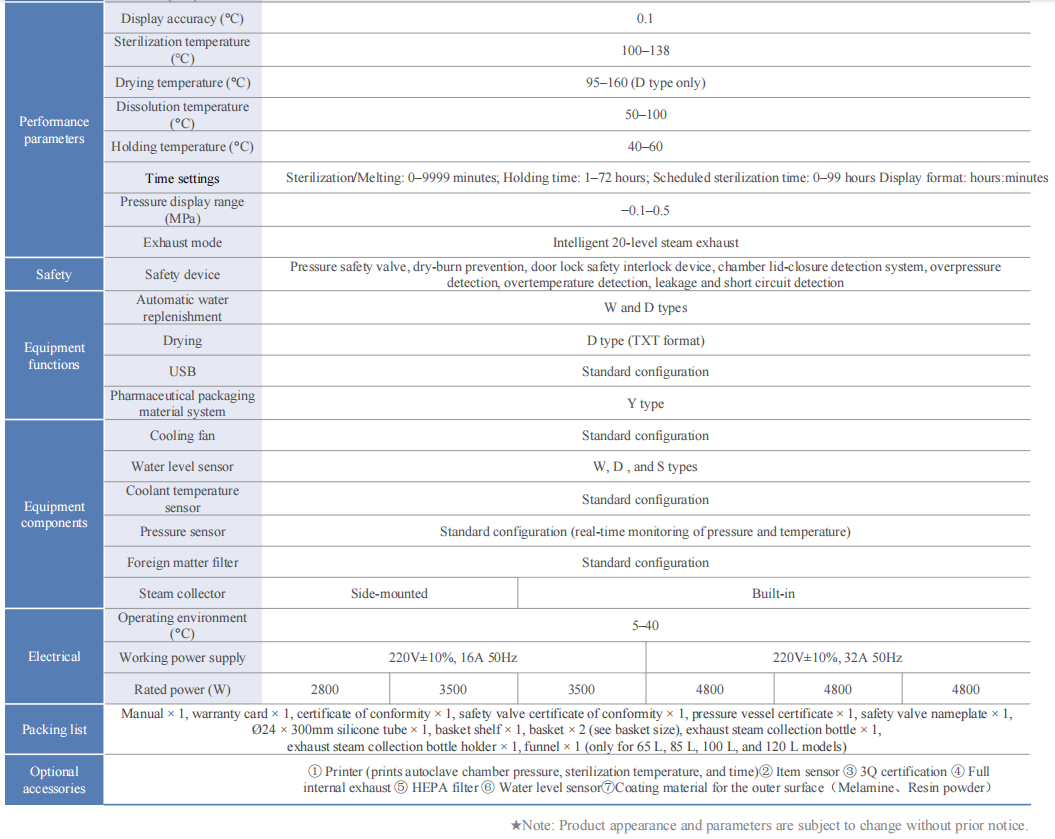

Standard configuration with dual hardware and software dry-burn prevention function, overtemperature protection system, and overpressure protection safety valve.

The heating function stops when the lid is opened.

Equipped with a water level sensor and unique software-controlled dry-burn prevention technology, offering multiple protection mechanisms to prevent dry burning.

Optional pressure gauge configurable up to 0.5, with overcurrent and short-circuit protection systems.

Self-sensing pressure interlock device, lid-closure detection system, and leakage protection device.

Real-time monitoring of chamber temperature; automatic power-off protection activates if temperature exceeds limits or abnormal heating occurs.

Maximum sterilization temperature can be set up to 138°C.

Freertos embedded operating system.

Uses the PT1000 sensor for precise temperature control with 0.1°C display accuracy.

After sterilization is complete, the exhaust valve can release steam at 20 adjustable speeds.

Features automatic detection and verification of the temperature and pressure relationship, ensuring true saturated steam conditions are reached.

F0 value testing function included.

Standard configuration with USB drive for real-time data recording.

Dual temperature sensors detect both air and water temperatures for enhanced safety. Boiling point temperature can be adjusted based on altitude.

Exhaust temperature can be adjusted within 0–25°C above the boiling point.

Automatically detect cold air discharge, ensuring proper steam exhaust functionality, and maintains a contamination-free environment.